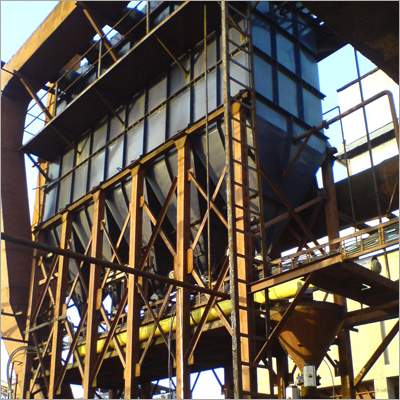

Dust Fume Extraction Systems

Dust Fume Extraction Systems Specification

- Instruments Type

- Industrial Extraction System

- Sensor Type

- Differential Pressure, Airflow Sensors

- Orientation

- Vertical / Horizontal

- Efficiency

- >99%

- Usage & Applications

- Industrial Dust and Fume Extraction, Welding Shops, Grinding Areas, Pharma Plants, Foundries

- Scrubber Type

- Wet / Dry Scrubber as per requirement

- Air Flow

- 1,000 to 30,000 m3/hr

- Temperature

- Ambient to 60°C

- Power Source

- Electric

- Measurement

- Particulate concentration, Air quality

- Product Type

- Dust Fume Extraction Systems

- Material

- Mild Steel (MS) / Stainless Steel (SS)

- Cooling System

- Air cooled / Water cooled

- Noise Level

- <70 dB(A)

- Processing Time

- Continuous Operation

- Capacity

- Up to 30,000 m3/hr

- Voltage

- 415V / 380V / 230V, 3 Phase, 50Hz

- Dimension (L*W*H)

- Customized as per site requirement

- Surface

- Powder Coated / Painted

About Dust Fume Extraction Systems

We are distinguished firm engaged in offering high quality Dust Fume Extraction Systems that are extensively demanded in various industries. Our offered systems are manufactured under the guidance of our ingenious professionals using the finest grade components with the help of contemporary techniques as par the international norms of quality. The systems provided by us are broadly known for their anti-corrosive nature and robustness. Furthermore, our clients can purchase these Dust Fume Extraction Systems from us at pocket friendly prices.

Features:

-

Excellent performance

-

Energy efficient

-

Rust resistance

-

Low maintenance

Advanced Industrial Air Quality Management

Our extraction systems utilize high-efficiency filtration, wet or dry scrubbing, and intelligent monitoring to ensure safe, clean air in industrial spaces. With flexible material and orientation choices, they integrate seamlessly with diverse setups, providing sustained performance even during continuous operation. Designed for heavy-duty environments, these systems protect personnel and enhance equipment longevity.

Customizable Design to Suit Every Application

Each system is dimensioned according to your site requirements, allowing optimal placement and functioning. From foundries to pharma plants, you can choose between mild steel and stainless steel, vertical or horizontal orientation, and cooling types. The capacity and airflow range can be adjusted for small workshops or large-scale facilities, offering tailored protection against dust and fumes.

FAQs of Dust Fume Extraction Systems:

Q: How does the Dust Fume Extraction System ensure efficient removal of industrial pollutants?

A: The system uses high-grade filtration and either wet or dry scrubber technology, which captures and neutralizes dust and fumes. Its >99% efficiency guarantees cleaner air, safeguarding worker health and reducing airborne contamination within industrial settings.Q: What are the available capacity and airflow ranges for the extraction system?

A: The extraction system handles airflows between 1,000 to 30,000 m/hr, accommodating various facility sizesfrom compact workshops to large-scale factories. The processing capacity is scalable according to specific site demands.Q: When is it necessary to choose between air-cooled and water-cooled models?

A: Air-cooled systems are best suited for environments with moderate temperatures and simpler installations, while water-cooled models are ideal for sites with higher ambient heat or demanding continuous operation. Selection depends on specific cooling requirements and operational conditions.Q: Where can the extraction system be installed, and how are dimensions determined?

A: The system can be installed in welding shops, grinding areas, foundries, pharmaceutical plants, and any industrial location dealing with dust or fumes. Its dimensions are customized based on site measurements to ensure seamless integration with existing infrastructure.Q: What is the process for monitoring air quality and particulate concentration?

A: Integrated differential pressure, airflow, and temperature sensors provide real-time measurement of particulate levels and air quality. These instruments enable ongoing monitoring and adjustment, ensuring sustained compliance with safety and environmental standards.Q: How does the system benefit industrial workplaces?

A: By continuously extracting dust and fumes, the system significantly improves air purity, minimizing health risks for workers, reducing equipment wear, and maintaining regulatory compliance. Its low-noise design and high efficiency also contribute to a safer, quieter working environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dust Extraction System Category

Dust Extraction

Automation Grade : Semi Automatic

Usage & Applications : Industrial Dust Removal, Factories, Workshops, Manufacturing Units

Power Source : Electric

Voltage : 415 V

Material : Mild Steel

Product Type : Dust Extraction System

Dust Extraction System

Automation Grade : Semi Automatic

Usage & Applications : Industrial

Power Source : Electrical

Voltage : 220440 Volt (v)

Material : Mild Steel

Product Type : Dust Extraction System

Fume Extraction Systems

Automation Grade : Semi Automatic

Usage & Applications : Industrial

Power Source : Electrical

Voltage : 440 Volt (v)

Material : Mild Steel

Product Type : Fume Extraction Systems