Dust Extraction

Dust Extraction Specification

- Temperature

- Up to 60°C

- Power Source

- Electric

- Measurement

- Particulate Concentration

- Sensor Type

- Optical Particle Sensor

- Automation Grade

- Semi Automatic

- Orientation

- Vertical

- Usage & Applications

- Industrial Dust Removal, Factories, Workshops, Manufacturing Units

- Instruments Type

- Dust Collector

- Scrubber Type

- Wet Scrubber

- Efficiency

- > 99%

- Air Flow

- 2000 m³/h

- Product Type

- Dust Extraction System

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- Below 80 dB

- Reactor Thickness

- 6 mm

- Processing Time

- Continuous

- Capacity

- 2000 m³/h

- Voltage

- 415 V

- Weight

- 420 kg

- Dimension (L*W*H)

- 1650 x 890 x 1830 mm

- Surface

- Powder Coated

About Dust Extraction

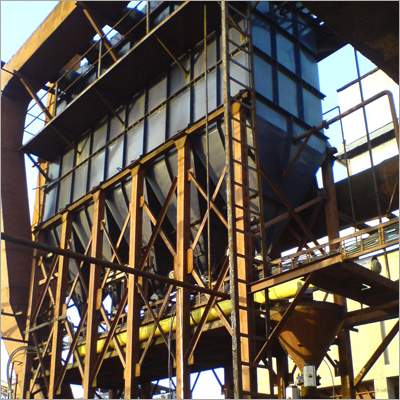

Dust Extraction

We are offering to our clients, dust extraction systems which are mandatory part of all chemical process as well as material handling plant that may pollute atmosphere beyond permissible limit.

Exceptional Performance and Reliability

Our dust extraction unit delivers continuous, high-capacity operationhandling up to 2000 m/h airflow. With a vertical, semi-automatic wet scrubber and precision particle sensing, it provides consistently superior dust removal for factories and workshops. The sturdy mild steel build and powder-coated surface ensure durability and easy maintenance.

Advanced Air Quality Protection

Utilizing optical particle sensors, our system accurately monitors and collects particulate matter, keeping the work environment safe and compliant with regulations. The wet scrubber design captures dust and minimizes emissions, maintaining air quality to protect workers and equipment.

Flexible Industrial Applications

Custom-built for industrial settings, this dust collector is suitable for manufacturing units, factories, and workshops. Its robust performance and compact design fit seamlessly into various production lines, ensuring hassle-free integration without compromising floor space.

FAQs of Dust Extraction:

Q: How does the dust extraction system maintain high efficiency during continuous operation?

A: The system employs a wet scrubber design and an optical particle sensor, which ensures over 99% dust removal efficiency. The air-cooled mechanism and robust construction allow for uninterrupted, continuous processing, maintaining optimal air quality throughout operational hours.Q: What are the primary benefits of using this dust collector in industrial applications?

A: Key advantages include highly efficient particulate removal, reduced noise (below 80 dB), reliable performance up to 60C, and durable mild steel construction. This leads to cleaner workspaces, enhanced worker safety, and prolonged machinery lifespan.Q: When should factories or workshops opt for a wet scrubber type dust extraction system?

A: Wet scrubbers are ideal when dealing with challenging dust particles or when a high removal efficiency is required, such as in manufacturing environments or workshops where airborne particulates must be controlled consistently.Q: Where can this dust extraction unit be installed?

A: This unit is best suited for installation in industrial environments such as factories, manufacturing units, and workshops. Its compact, vertical orientation and moderate footprint (1650 x 890 x 1830 mm) allow for flexible placement on production floors.Q: How does the automation grade affect the operation of this equipment?

A: With its semi-automatic operation, the system requires minimal manual intervention while maintaining efficient dust extraction. This balance promotes user convenience, reliability, and consistent performance.Q: What is the process for measuring and monitoring dust concentrations?

A: The integrated optical particle sensor continuously measures particulate concentration in the air, providing real-time feedback to ensure efficient dust removal and workplace safety.Q: What maintenance procedures are recommended for sustained system efficiency?

A: Regular inspection of the wet scrubber components, checking sensor accuracy, and routine cleaning of air pathways help maintain efficiency. The durable powder-coated finish protects the system from corrosion and simplifies upkeep.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dust Extraction System Category

Dust Fume Extraction Systems

Material : Mild Steel (MS) / Stainless Steel (SS)

Usage & Applications : Industrial Dust and Fume Extraction, Welding Shops, Grinding Areas, Pharma Plants, Foundries

Product Type : Dust Fume Extraction Systems

Voltage : 415V / 380V / 230V, 3 Phase, 50Hz

Power Source : Electric

Fume Extraction Systems

Material : Mild Steel

Usage & Applications : Industrial

Product Type : Fume Extraction Systems

Voltage : 440 Volt (v)

Power Source : Electrical

Automation Grade : Semi Automatic

Dust Extraction System

Material : Mild Steel

Usage & Applications : Industrial

Product Type : Dust Extraction System

Voltage : 220440 Volt (v)

Power Source : Electrical

Automation Grade : Semi Automatic